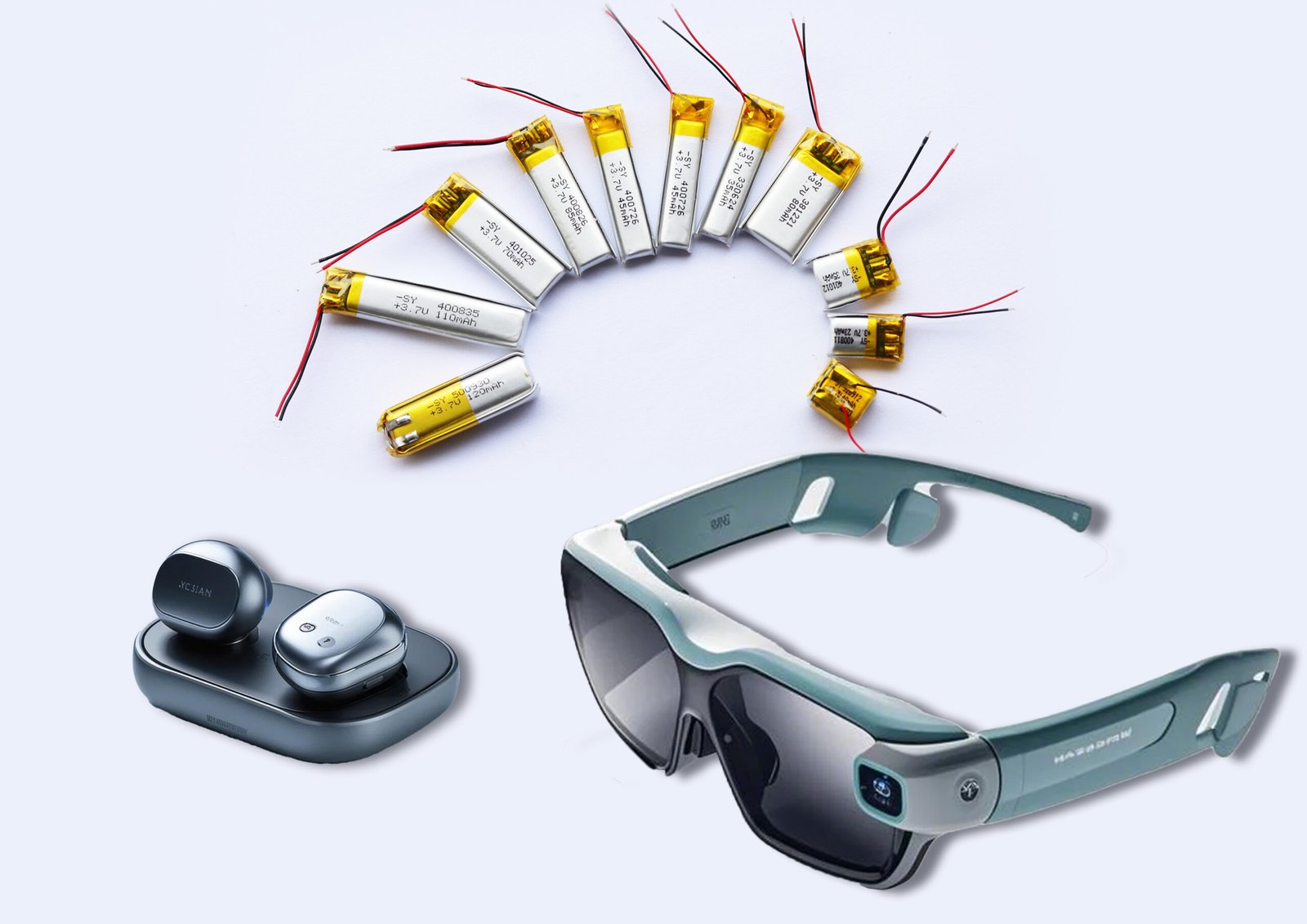

Exploding batteries, overheating frames, or sudden shutdowns—none of these are acceptable in a device worn on your face.

Smart glasses manufacturers test battery safety and reliability through rigorous chemical analysis, mechanical impact testing, thermal management simulations, and international certification protocols.

If you’ve ever wondered how tiny batteries inside smart glasses stay safe and stable while resting next to your temples, the answer lies in complex, standardized testing systems. Let’s explore what goes into making sure these batteries are safe for everyday wear.

Table of Contents

ToggleWhat Is Battery Composition Analysis and Why Does It Matter?

The foundation of any reliable battery is its chemical makeup. If the chemistry isn’t stable, no amount of design can save the product.

Manufacturers start with a deep analysis of raw materials like lithium cobalt oxide and graphite to ensure consistency, purity, and safety.

Key Battery Components

| Component | Function |

|---|---|

| Lithium Cobalt Oxide (LiCoO₂) | Cathode material – high energy density |

| Graphite | Anode – stable during charge cycles |

| Electrolyte | Enables ion flow between electrodes |

| Separator | Prevents short circuits |

Each batch of these materials is tested using spectroscopy, chromatography, and microscopy to confirm purity levels and particle structure. Impurities—even at 0.1%—can destabilize battery performance.

This raw material testing is a pre-condition for downstream safety—a bad batch of cathode material can mean explosive failures under heat or stress.

How Is Quality Controlled During Early Production?

Making a safe battery isn’t just about chemistry—it’s about process discipline from the first assembly stage.

Initial quality control includes raw material inspection, electrode alignment checks, and electrical performance testing.

Critical Early QC Steps

- Incoming Material Inspection: Verify specs and certifications of all components.

- Coating Thickness Checks: Uniform anode/cathode layers prevent imbalanced reactions.

- Cell Welding Inspection: Laser welding points are checked with high-precision optics.

- Electrical Testing: Voltage, resistance, and capacity are sampled before packaging.

These tests are conducted under ISO 9001 and IEC 62133 compliance frameworks to ensure traceability, documentation, and repeatability.

Faulty units are rejected before encapsulation, keeping defects from ever reaching your face.

How Are Batteries Designed to Prevent Physical Damage?

A smart glasses battery lives in a tight space next to sensitive electronics—and your face.

Battery safety begins with design: sealed casings, layered insulation, and placement far from high-contact areas like the nose bridge or lenses.

Design Safeguards

| Feature | Purpose |

|---|---|

| Metal casing (Al or SS) | Prevents puncture or swelling |

| Thermal insulation | Stops short-circuit due to heat |

| Overcharge protection | BMS shuts off at voltage thresholds |

| Fire-retardant padding | Prevents ignition in failure events |

Design teams test these features using 3D heat modeling and crash simulations before moving to real-world tests.

Batteries are also placed in the temple arms, away from high-impact zones like lenses, which protects both the device and the user.

How Is Thermal Management Validated?

Heat is the number one threat to lithium battery safety—especially when worn on the skin.

Manufacturers simulate and measure heat generation using thermal cameras, sensors, and calorimetry tools.

Key Thermal Tests

- Thermal Imaging: Reveals hotspots during charge/discharge cycles.

- Calorimetry: Measures how much heat a battery generates under load.

- Thermal Cycling: Repeated heating and cooling to test durability under environmental changes.

Smart glasses must maintain a surface temperature under 45°C even during peak usage. Engineers use graphite sheets and air gaps in the housing to improve cooling.

How Are Batteries Tested for Electrical Stability?

What happens if you charge and discharge 1000 times? A stable battery should still work.

Charge-discharge cycling tests measure how long a battery can maintain performance under repeated use.

Electrical Reliability Metrics

| Test Type | What It Measures |

|---|---|

| Cycle Life | How many full charges before degradation |

| Capacity Retention | % of original charge after X cycles |

| Internal Resistance | Measures wear or potential short circuits |

Most smart glasses batteries are rated for 300–500 cycles. Any drop of more than 20% capacity within 200 cycles is considered a fail.

Units are tested under standard, fast, and slow charging conditions to simulate real-world patterns.

How Are Short Circuit Scenarios Simulated?

Even with safeguards, accidents happen—what if a battery is shorted by mistake?

Short-circuit testing deliberately causes internal or external shorts to verify that the battery does not explode, leak, or overheat uncontrollably.

Safety Mechanisms Tested

- Thermal cutoff switches

- PTC (Positive Temperature Coefficient) devices

- Current limiters

During the test, engineers monitor temperature, internal pressure, and current flow in real-time using high-speed sensors.

These stress tests are mandatory for UN38.3, UL, and CE certifications.

How Do Physical Impact and Vibration Tests Work?

Smart glasses get dropped, tossed into backpacks, or slammed in drawers.

Impact and vibration testing simulates real-world mishandling and travel conditions to confirm that the battery remains safe.

Common Tests

| Test Type | Procedure |

|---|---|

| Drop Test | Dropped from 1–1.5m onto concrete |

| Crush Test | Apply pressure until deformation |

| Vibration Test | Simulate transport in trucks or planes |

After each test, units are opened or X-rayed to detect swelling, punctures, or internal damage.

Some manufacturers also conduct humidity and salt spray tests for export readiness.

Which Certifications Must Smart Glasses Batteries Pass?

Every safe battery comes with a trail of certifications behind it.

Smart glasses batteries are certified under international standards that guarantee safety in shipping, wear, and operation.

Key Certifications

| Certification | Purpose | Region |

|---|---|---|

| UL | Electrical and fire safety | Global (US-led) |

| UN38.3 | Transport safety (vibration, thermal) | Global |

| RoHS | Limits hazardous substances | Europe |

| PSE | Electrical safety in consumer devices | Japan |

| KC | Quality and compliance | South Korea |

Without these certifications, smart glasses cannot legally be exported or sold in major markets.

Conclusion

Smart glasses manufacturers ensure battery safety through material analysis, mechanical testing, thermal modeling, and rigorous international compliance—making sure that what’s resting on your face is as safe as it is smart.