Lithium polymer ion (LiPo) batteries are renowned for their lightweight, compact, and customizable designs1. But how flexible are they really? Flexibility in battery design is critical for modern technologies like wearable devices2, foldable electronics3, and medical implants4.

**Lithium polymer ion batteries5 are highly flexible in form factor, offering design versatility and the ability to conform to a variety of shapes, including ultra-thin and curved designs.**

Let’s explore how their structure enables flexibility and how this impacts their applications in various industries.

Table of Contents

ToggleWhat makes lithium polymer batteries flexible?

The flexibility of lithium polymer batteries6 is primarily due to their unique construction7. Unlike traditional lithium-ion batteries, which are encased in rigid metal housings8, LiPo batteries use a pouch-style design9.

Key Features Contributing to Flexibility:

-

- Made from aluminum-laminated plastic film, the housing is lightweight and malleable, allowing the battery to conform to non-traditional shapes.

- This eliminates the need for rigid cylindrical or prismatic casings.

-

- LiPo batteries are constructed using wafer-thin layers of electrodes, separators, and electrolyte, enabling ultra-thin designs (less than 1 mm thick in some cases).

-

- Unlike liquid electrolytes in traditional lithium-ion batteries, LiPo batteries use a gel-like or solid polymer electrolyte, enhancing their flexibility and safety by reducing the risk of leakage.

-

- The lack of rigid housing allows manufacturers to create batteries in virtually any shape or size, from curved designs for wearables to large, flat cells for industrial applications.

These features make LiPo batteries a preferred choice for applications where form factor flexibility is a critical requirement.

How flexible are LiPo batteries in practical applications?

LiPo batteries can be designed to fit the unique demands of a wide range of industries and products14. Below are some examples of their flexibility in real-world applications.

Ultra-Thin Designs

LiPo batteries can be manufactured as thin as 0.5 mm15, making them ideal for:

- Wearables:16 Smartwatches and fitness trackers.

- Medical Devices:17 Hearing aids, insulin pumps, and other portable equipment.

- Consumer Electronics: Ultra-slim laptops and smartphones.

Curved and Custom Shapes

The malleability of LiPo batteries allows for innovative designs, including:

- Foldable Screens: Batteries that bend to fit devices with flexible displays.

- IoT Devices: Batteries customized for irregular shapes in smart home systems and trackers.

- Automotive: Conforming to unconventional shapes in electric vehicles and drones.

Emerging Innovations in Flexibility

Recent research, such as stretchable lithium-ion polymer batteries, takes flexibility even further:

- Elastic Batteries: Incorporate stretchable polymer electrolytes that can expand up to 5000% of their original size, ideal for wearable health monitors and implantable devices.

- Foldable Components: Origami-style designs allow batteries to fold and unfold without compromising energy storage capacity.

These advances demonstrate how flexible LiPo batteries are evolving to meet the demands of futuristic technologies.

How does our company enhance LiPo battery flexibility?

As a leading manufacturer of lithium polymer batteries, we specialize in delivering customized solutions to meet the unique requirements of our clients across various industries.

Key Features of Our Batteries:

-

Customizable Shapes and Sizes:

- We design batteries to fit specific product dimensions, whether it’s a curved device, ultra-thin wearable, or compact IoT gadget.

-

Advanced Materials:

- By using high-quality polymer electrolytes and flexible housing materials, we ensure maximum durability and adaptability.

-

Safety and Performance:

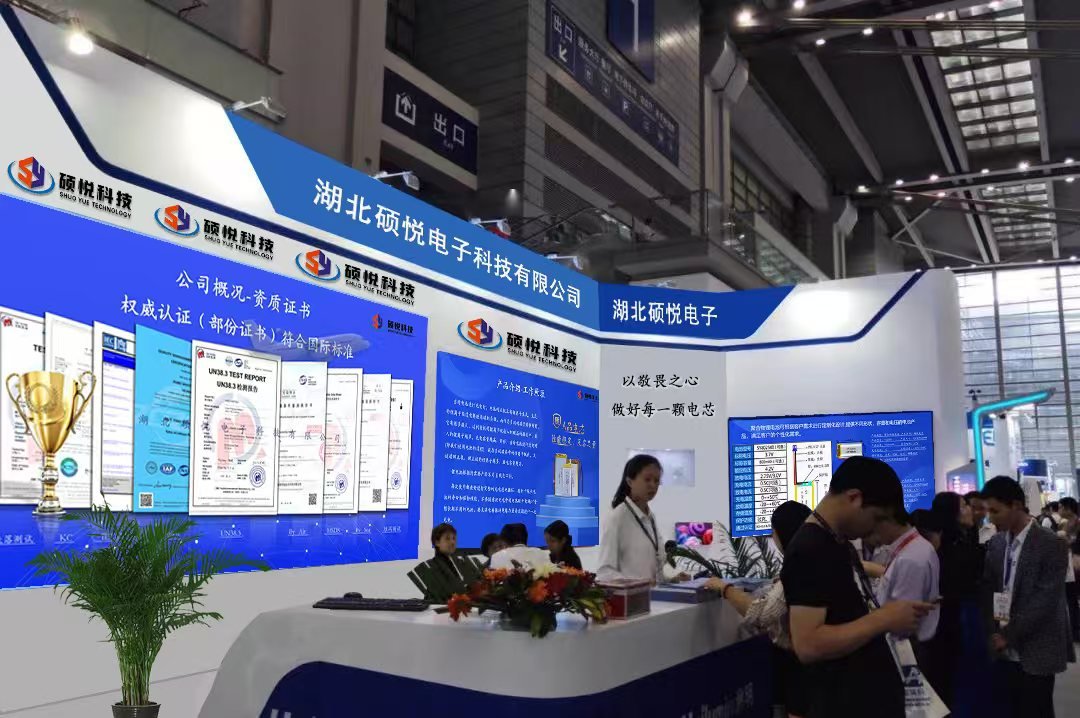

- Our batteries are rigorously tested to comply with certifications like UN38.3, CE, and RoHS, ensuring safe and reliable operation in diverse applications.

-

R&D for Emerging Technologies:

- We continually invest in research to develop stretchable and foldable battery technologies, staying ahead of industry trends.

Certifications We Provide:

| Certification | Focus Area | Products Supported |

|---|---|---|

| UN38.3 | Transport safety | Lithium polymer and Li-ion batteries |

| RoHS | Environmental compliance | Wearables, IoT devices, and medical applications |

| ISO 9001 | Quality management | All battery solutions |

Challenges and Limitations of Flexible LiPo Batteries

Despite their flexibility, LiPo batteries have certain limitations:

- Swelling During Use:

- Batteries may expand by up to 10% during charge/discharge cycles, requiring careful design of battery compartments to prevent damage.

- Durability Concerns:

- Soft pouch housings are less robust than metal casings and must be handled with care to avoid punctures or damage.

- Cost of Customization:

- Creating highly specialized battery designs can increase production costs, particularly for small-scale applications.

By addressing these challenges, we ensure that our batteries meet both performance and design requirements.

Conclusion

Lithium polymer ion batteries are highly flexible, offering unparalleled versatility in size, shape, and application. From ultra-thin designs for wearables to innovative curved and stretchable batteries, their adaptability makes them an essential component of modern technology. Our company’s expertise in customized battery solutions ensures that we can meet the unique demands of industries ranging from consumer electronics to medical devices and beyond.

-

Learn why LiPo batteries are ideal for space-constrained applications. ↩

-

Explore how LiPo batteries power smartwatches and health trackers. ↩

-

Understand how LiPo batteries enable foldable electronic devices. ↩

-

Learn how flexible batteries support implantable medical devices. ↩

-

Get an overview of LiPo battery technology and applications. ↩

-

Compare LiPo flexibility with lithium-ion and solid-state batteries. ↩

-

Understand why LiPo batteries have greater flexibility. ↩

-

Learn how battery casings impact durability and flexibility. ↩

-

Understand how pouch batteries enhance flexibility and safety. ↩

-

Explore how soft casings impact battery performance. ↩

-

Discover the minimum thickness possible for LiPo batteries. ↩

-

Compare different electrolyte materials for flexibility and safety. ↩

-

Learn how manufacturers create custom battery sizes. ↩

-

Understand how LiPo batteries fit into various sectors. ↩

-

Find out the current limits of ultra-thin battery design. ↩

-

Discover why wearables rely on LiPo battery designs. ↩

-

Learn how flexible batteries support life-saving medical technology. ↩