Struggling to balance battery performance, size, and cost in your electronic devices?

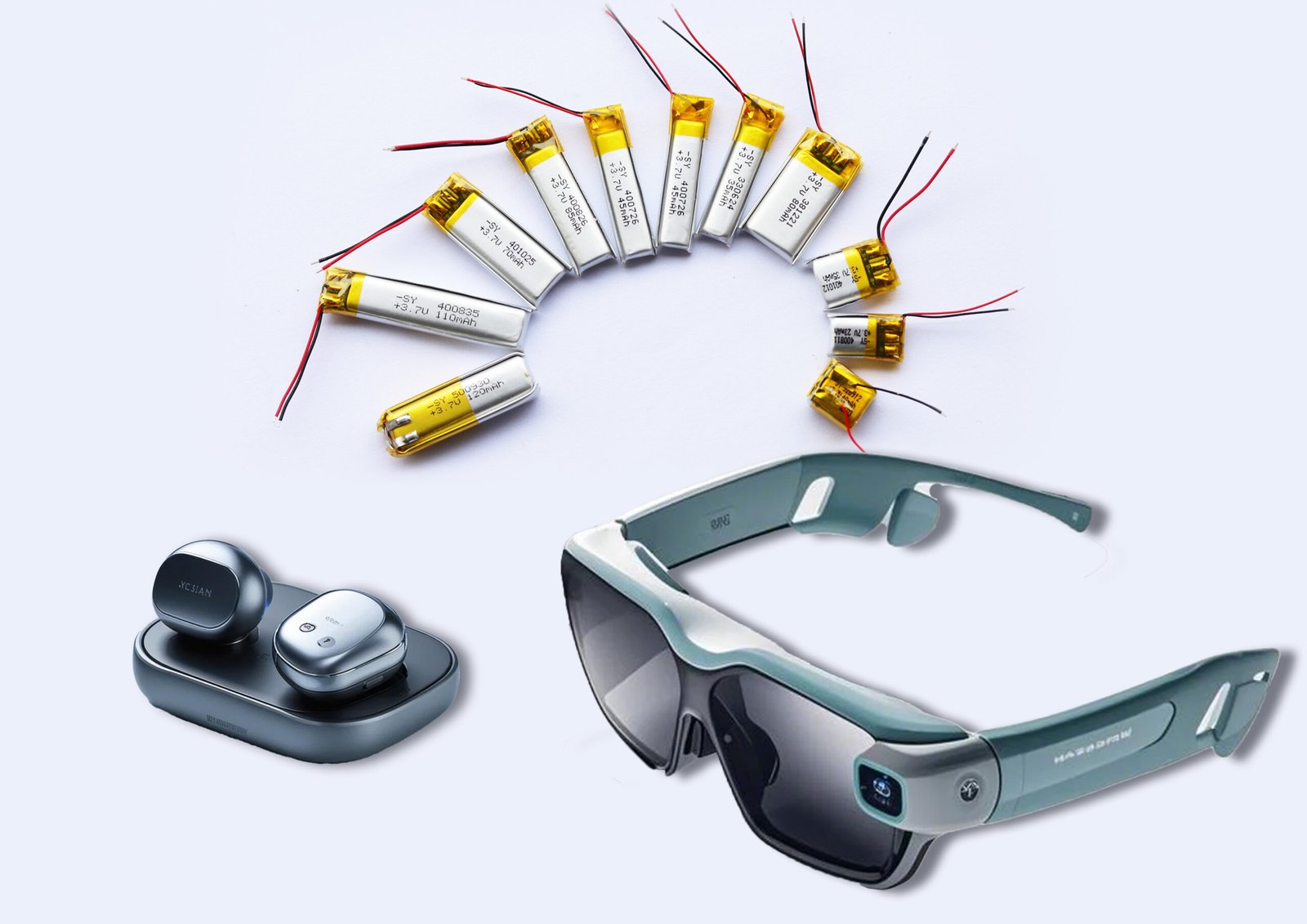

Small lithium battery suppliers are essential partners in the consumer electronics industry—they ensure compact power, high energy density, and product scalability in today’s connected world.

These suppliers aren’t just component providers. They’re innovation partners, production backbones, and quality gatekeepers that define your device’s real-world performance.

Table of Contents

ToggleContent

- How do small lithium battery suppliers support evolving market demands?

- What role do suppliers play in stabilizing and scaling the electronics supply chain?

- How does supplier innovation drive device performance and design?

- Why is supplier quality control critical to consumer safety?

- What are suppliers doing to meet sustainability and compliance needs?

How do small lithium battery suppliers support evolving market demands?

Your smartwatch lasts all day. Your earbuds charge in minutes. Behind this magic? Tiny batteries built to do more in less space.

Battery suppliers meet growing consumer expectations by improving capacity, miniaturization, and energy efficiency in their battery designs.

🔋 Key Consumer Device Demands

| Device Type | Battery Needs |

|---|---|

| Smartphones | High density, fast charge |

| Wearables | Tiny size, long cycle life |

| Wireless Earbuds | Mini shape, >5 hours playtime |

| Smart Glasses | Flexibility, lightweight |

Suppliers now deliver:

- Cells <20mm thick

- Energy densities up to 300 Wh/kg

- 1C–3C charging capabilities

They must anticipate device makers’ roadmap 6–12 months ahead and prepare custom specs accordingly.

A reliable supplier doesn’t just wait for orders—they help design batteries for products that don’t exist yet.

What role do suppliers play in stabilizing and scaling the electronics supply chain?

Delays in battery shipments can halt entire production lines.

Strong lithium battery suppliers anchor the electronics supply chain with just-in-time logistics, flexible production, and material security.

🏭 Supplier’s Core SCM Responsibilities

- Source lithium, cobalt, and separator materials ethically

- Maintain buffer inventory for high-volume clients

- Offer urgent delivery for product launches

- Adapt batch sizes to client forecast changes

Suppliers often invest in:

- Dual-source material strategies

- Regional warehousing (for Asia/US/EU)

- ERP systems to track inventory in real time

This reliability is why top electronics brands form multi-year battery contracts with trusted suppliers:contentReference[oaicite:0]{index=0}.

How does supplier innovation drive device performance and design?

Your product design can only be as innovative as your battery partner.

Suppliers who invest in R&D—like solid-state electrolytes, high-silicon anodes, and smart BMS—directly enable sleeker, faster, safer devices.

🚀 Innovations by Top Battery Suppliers

| Technology | Impact on Devices |

|---|---|

| Solid-State Batteries | Safer, thinner, higher energy |

| Silicon Anodes | 30–50% more capacity in same volume |

| Flexible Cells | Used in AR glasses, smart textiles |

| Real-time BMS | Device health monitoring, longer life |

Leading battery makers test:

- Charging time reduction (2C–3C speeds)

- Over-temperature shutdown logic

- Smart balancing across multi-cell designs

Their labs often co-develop prototypes with OEMs, testing form factor + performance fit in real devices.

Without a forward-looking supplier, you’re building tomorrow’s product on yesterday’s tech.

Why is supplier quality control critical to consumer safety?

One defective cell can recall an entire product line.

Reliable suppliers apply rigorous IQC, FQC, OQC, and batch-traceable testing to ensure product safety in mass production.

🛡️ Key QC Procedures from Reputable Factories

- IQC: Incoming materials (foil, electrolyte) tested for purity

- FQC: Voltage, IR, capacity, cycle test of each pack

- OQC: Final packaging + label check

- Safety Tests: Overcharge, short-circuit, thermal exposure

Suppliers like SY follow:

- ISO 9001 quality standards

- CE, FCC, UL, UN38.3 certifications:contentReference[oaicite:1]{index=1}

- Good yield rates (≥98% for wearables and CE devices)

Ask suppliers: “Can I see your last 3 months’ batch test reports?”

Real partners will show trends and failure handling protocols.

What are suppliers doing to meet sustainability and compliance needs?

Today’s buyers want performance—with responsibility.

Leading suppliers are integrating RoHS compliance, recycling programs, and green manufacturing into their operations.

🌱 Supplier Eco-Responsibility Measures

| Practice | Compliance Standard |

|---|---|

| No hazardous metals | RoHS / REACH |

| Recyclable packaging | ISO 14001 |

| Take-back / recycling | In-house or 3rd party |

| Energy-efficient lines | ESG reporting ready |

Some even offer “green cell” product lines made with:

- Cobalt-free cathodes

- Recycled lithium sources

- Reduced-carbon factory operations

As sustainability becomes a sourcing condition—not a bonus—these suppliers gain access to high-tier OEM contracts.

Conclusion

Small lithium battery suppliers are the hidden enablers of today’s electronics boom. They power not only devices, but also innovation, safety, and global scalability.